Housing material: SUS304 or custom SUS316/316L

Filtration accuracy: 1-10000um (micron) filtration accuracy

Working pressure: 0.6-1.6Mpa

Structure: housing, filter element (custom), tri-clamp or oterh connector

Description

Y-strainer is an indispensable filtering device for the pipeline system that transports media. The Y-strainer is usually installed at the inlet end of a pressure reducing valve, pressure relief valve, fixed water level valve or other equipment to remove impurities in the medium, to protect the normal running of valves and equipment.

Application

Y-strainer has the characteristics of advanced structure, small resistance and convenient sewage discharge. Y-strainer widely used for water, oil and gas/air filtration.

Working principle

When the fluid enters the filter cartridge with customized pore size, the impurities are blocked in the filter cartridge, and the clean liquid is discharged from outlet. When cleaning is needed, just take out the detachable filter element, reinstall it after cleaning.

Y-strainer, also known as dirt remover and filter valve, its function is to intercept mechanical impurities in the medium, such as rust, sand in sewage, a small amount of solid particles in liquid, etc., to protect the accessories on the pipeline from wear and blockage.

Model and size

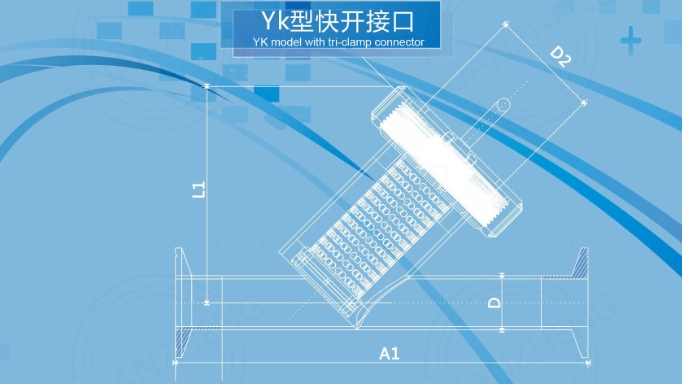

| YK model | |||||

| Size(mm) | Model | D | A1 | L1 | D2 |

| 1” | Y25K | 25 | 190 | 90 | 51 |

| 1-1/4” | Y32K | 32 | 200 | 102 | 51 |

| 1-1/2” | Y38K | 38 | 200 | 107 | 51 |

| 2” | Y51K | 51 | 220 | 140 | 76 |

| 2-1/2” | Y63K | 63 | 260 | 165 | 89 |

| 3” | Y76K | 76 | 280 | 190 | 102 |

| 3-1/2” | Y89K | 89 | 295 | 225 | 133 |

| 4” | Y102K | 102 | 340 | 249 | 133 |

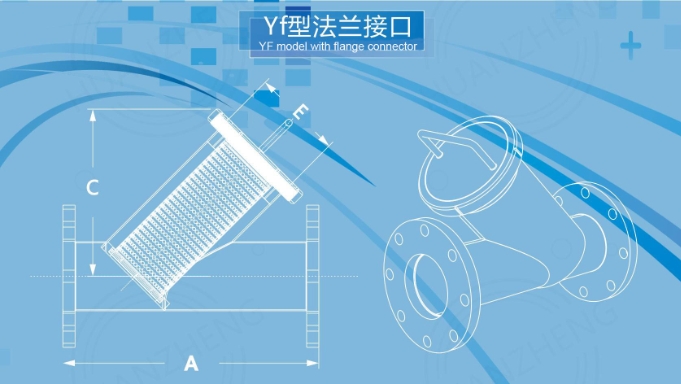

| YF model/ unit:mm | ||||

| Model | A | C | E | Flange |

| Y25F | 216 | 90 | 51 | DN20 |

| Y32F | 226 | 102 | 51 | DN25 |

| Y38F | 228 | 107 | 51 | DN32 |

| Y51F | 252 | 140 | 76 | DN50 |

| Y63F | 290.1 | 165 | 89 | DN50 |

| Y76F | 316 | 190 | 102 | DN65 |

| Y89F | 331 | 225 | 133 | DN80 |

| Y102F | 377.9 | 249 | 133 | DN100 |

Filter material

We use top quality wire mesh, wire mesh uses both the diameter and weft mesh sizes, which are normal. The filter mesh has no mesh defects, and the material complies with the national standard.

High quality stainless steel pipes are used to produce housings, the nickel and chromium content are both standard.

Welding

use high-frequency welding to ensure that the welding bead is not broken, the welding is firm. We use melt welding at both ends, which is firm, burr free, beautiful and flat, and has no leakage points. This is a welding level that other manufacturers in China cannot achieve! it is easy to clean, free of impurities, and has a long service life. The material is made according to national standards.

Material cutting

We use wire cutting machine to reduce the residue generated during cutting, and make sure the size is correct and improve the precision.

Other manufacturers directly use cutting machines to cut, but the burrs cannot be thoroughly treated, and stainless steel slag will fall off during use, affecting subsequent equipment.

Copyright © Hebei Huanzheng Filter Equipment Co., Ltd. All Rights Reserved